Oil-free rotary screw compressors

ZR 300-750 & ZR 400-900 VSD

Setting the standard in energy efficiency, safety and reliability

The shortest route to superior productivity is to minimize

operational cost while maintaining an uninterrupted supply of the

right quality of air. The Atlas Copco Z compressor series is

focused on effectively saving energy, ensuring product safety– only

oil-free machines exclude contamination risks for 100% – and

guaranteeing the utmost reliability around the clock. And not just

today, but day after day, year after year, with minimal maintenance

cost, few service interventions and long overhaul intervals.

Advantage:

Highest reliability

For 60 years, Atlas Copco Z compressors have set the benchmark for

durability. They are built using long-standing internal engineering

practices, and are designed and manufactured according to ISO 9001,

ISO 14001, ISO 22000 & OHSAS 18001. The high-end ZR uses

time-proven state-of-the-art screw technology, cooling and

pulsation dampers and provides you with the highest reliability.

100% oil-free compressed air

The ZR offers you 100% pure, clean air that complies with ISO

8573-1 CLASS 0 (2010) certification. This means zero risk of

contamination; zero risk of damaged products; zero risk of losses

from operational downtime; and zero risk of damaging your company’s

hard-won professional reputation.

Maximum energy efficiency

The ZR’s superior oil-free screw elements provide the optimum

combination of high Free Air Delivery (FAD) with the lowest energy

consumption. Ample sized cooling, low pressure drops and an

extremely efficient drive train result in the highest compressor

package efficiency.

The most complete package

With the ZR compressor, Atlas Copco provides a superior solution

without hidden costs. The totally integrated, ready-to- use package

includes internal piping, coolers, motor, lubrication and control

system. Installation is fault-free, commissioning time is low and

no external instrument air is required.You simply plug and run.

Global presence - local service

Our aftermarket product portfolio is designed to add maximum value

for our customers by ensuring the optimum availability and

reliability of their compressed air equipment with the lowest

possible operating costs. We deliver this complete service

guarantee through our extensive service organization,maintaining

our position as leader in compressed air.

100% certified oil-free air

Atlas Copco is renowned for designing and manufacturing some of the

most durable oil-free screw compressors. The ZR high-end rotary

screw compressor comes out of this strong tradition. Ideal for

industries where high-quality oil-free air is key, the ZR offers

the highest reliability and safety in combination with low energy

costs.

Electronics

• Clean, dry, high-quality air (Class 0) is essential,produced with

optimal energy efficiency.

• Applications include the removal of microscopic debris from the

surfaces of computer chips and computer boards.

Textiles

• Easy and quick installation.

• A completely, fully integrated, ready-to-use solution.

Oil & gas

• Years of experience in providing compressed air for the oil & gas

industry.

• 100% oil-free compressed air for control/instrument air or buffer

air.

• Strong global support network to provide 24/7 assistance.

Automotive

• To maximize productivity in the automotive industry,downtime has

to be eliminated.

• An integrated package designed for long-lasting performance is

crucial.

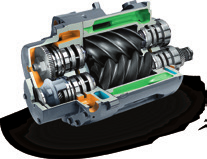

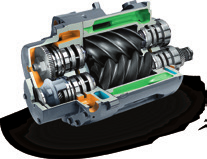

Proven Z technology

1.Throttle valve with load/unload regulation

• No external air supply required.

• Mechanical interlock of inlet and blow-off valve.

• Low unload power.

2.World-class oil-free compression element

• Unique Z seal design guarantees 100% certified oil-free air.

• Atlas Copco superior rotor coating for high efficiency and

durability.

• Cooling jackets.

3.High-efficiency coolers and water separator

• Corrosion resistant stainless steel tubing.

• Highly reliable robot welding; no leakages.

• Aluminium star insert increases heat transfer.

• Water separator with labyrinth design to efficiently separate the

condensate from the compressed air.

• Low moisture carry-over protects downstream equipment.

* Only for ZR water-cooled versions.

4.Powerful motor + VSD

• TEFC IP55 motor protects against dust and chemicals.

• Continuous operation under severe ambient temperature conditions.

• Direct energy savings up to 35% with Variable Speed Drive (VSD)

motor.

• Full regulation between 30 to 100% of the maximum capacity.

5.Advanced Elektronikon®

• Large 5.7” sized color display available in 31 languages for

optimal ease of use.

• Controls the main drive motor and regulates system pressure to

maximize energy efficiency.

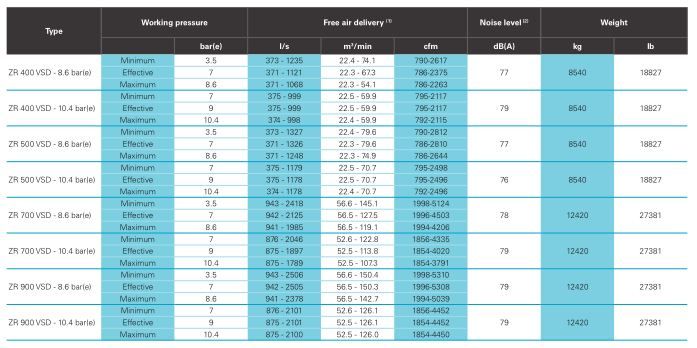

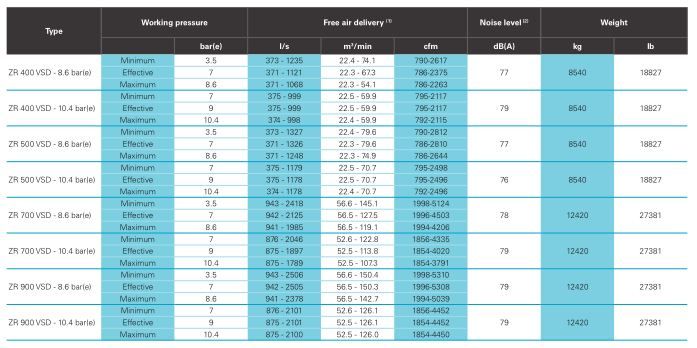

Technical specifications

ZR 300-750

ZR 400-900 VSD (50/60 Hz)